AI for Fuel, Not for Media-Slides: Yevhen Zherdiev’s View

As logistics giants race to scale AI infrastructure, a parallel movement is gaining momentum—smaller, more agile companies are building solutions that prioritize practical efficiency over sweeping disruption.

On May 21, 2025, Uber Freight unveiled the industry’s first large-scale AI-powered logistics network, which, according to the company, has already reduced the number of empty hauls by 10 to 15 percent. Just three days earlier, entrepreneur Yevhen Zherdiev, founder and CEO of Vizhen Inc., launched an AI-driven platform to help small and mid-sized logistics companies optimize fuel consumption and boost fleet efficiency.

We spoke with Yevhen to learn how artificial intelligence is helping logistics companies save money, automate operations, and adapt to shifting market conditions—and why the future of the industry is increasingly shaped not only in the headquarters of tech giants, but also in the hands of smart, focused innovators.

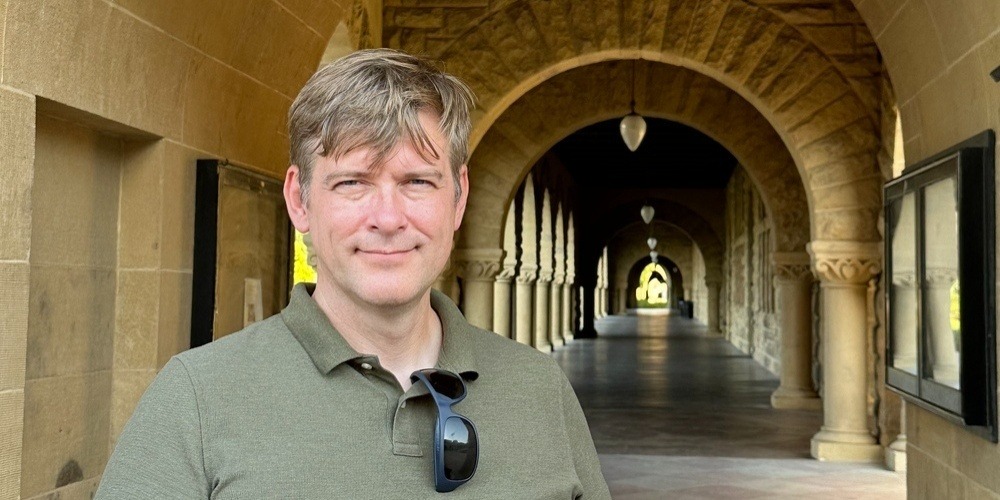

Yevhen Zherdiev is an economist with over 25 years of experience and a background in computer science with a focus on artificial intelligence, which he studied at Kyiv Polytechnic Institute in Ukraine. He led a company that provided IT infrastructure services and was involved in the development and maintenance of most of the IT-financial projects of Ukraine’s Ministry of Finance, including the creation of a fraud prevention system for government payments.

Yevhen progressed from an entry-level position at the State Tax Service to senior leadership roles. In his later years in public service, he focused on analyzing fuel sector legislation and proposing improvements aimed at enabling the implementation of advanced technologies to help the government prevent fraud amounting to over $1.5 billion annually.

Yevhen also contributed to the creation of Ukraine’s Unified Judicial Information and Telecommunication System, serving as the project lead for implementing the Financial and Administrative Subsystem of the State Judicial Administration, which supports over 20,000 employees. In the private sector, he developed ERP systems for nonprofit organizations, small and medium-sized enterprises, as well as industrial logistics and manufacturing companies.

Yevhen is a recognized member of the Institute of Electrical and Electronics Engineers (IEEE), one of the world’s most respected professional associations in technology. He is also the author of a peer-reviewed academic article on depreciation policy published in the journal Finance, Accounting and Auditing.

Yevhen, fuel costs, empty miles—there’s no shortage of logistics problems. Why is artificial intelligence finally being seen as a practical solution, rather than just a buzzword?

Logistics companies always operate with very tight margins. AI enables the real-time monitoring of variables that are challenging for humans or static tools to track, ranging from driver behavior to forecasting the cost-effectiveness of selected routes.

The value becomes clear when the results translate into tangible savings or task automation that eliminates the human factor. That’s when AI becomes a practical tool for real operations, not just something for slide presentations.

Where does AI deliver the biggest returns in logistics today: savings, speed, or stability? And why do you think fuel efficiency became such a clear starting point for innovation?

Fuel is one of the most significant controllable expenses in logistics. Any improvement is immediately reflected in financial reports. Our platform focuses on this because we work with small and mid-sized companies, where $500 to $3,000 per truck per month makes a significant impact. In many cases, that difference decides whether a route stays profitable. Fuel data is also more consistent and easier to quantify than other operational metrics, which makes it a natural place to apply AI first. Once savings are clear, building trust and introducing more automation later is easier.

Before launching Vizhen Inc., you built Ukraine’s court finance system for over 20,000 users and a fraud platform that saved $1.5 billion annually. What lessons from those large-scale projects are you applying now?

When a system supports thousands of users and billions of dollars in spending, the design must remain stable under pressure. I worked with teams that required clear logic, accurate workflows, and swift decision-making. That experience helped me focus on how to transform raw data into actionable steps that are easy to follow, even in fast-paced transport operations.

In 2021, you developed a fuel tracking system for Ukraine’s Tax Service that could recover up to $1 billion annually. How did that government project shape your current fuel efficiency and data integrity thinking?

That prototype taught me the critical importance of integrated data in understanding the full fuel lifecycle—from production and purchase to distribution and use. I observed how discrepancies at each stage resulted in losses. The same logic applies to commercial fleets: control begins with visibility. That project laid the foundation for how I now build business-focused systems.

You played a key role in building an accounting tool for a volunteer group supporting war-displaced people in Ukraine. How did that experience influence your shift from large-scale systems to helping smaller organizations with practical, focused tools?

Like for many others, the start of Russia’s war against Ukraine was a turning point for me. With prior experience in building accounting systems, I teamed up with a group of developers to make our contribution by helping people fleeing areas of active combat.

At the time, volunteers had no system in place. But once even a basic tracking tool was introduced, they were able to manage donations more effectively and provide better reporting to donors. This, in turn, helped them scale their operations dramatically, multiplying the amount of aid they could handle several times. It proved that even simple tools, when built with the right intention, can bring order and build trust. It also made me think even more deeply about the importance of clarity and usability in every system I design.

You’ve recently launched a new AI-powered platform to optimize fuel use. You project up to 20% monthly savings per truck based on early testing. What factors make that possible?

The MyMiles.ai platform utilizes real data from trucks, including speed, idle time, and fuel consumption patterns. We also factor in past and upcoming routes, recommend the best fueling locations, and monitor driver compliance and discipline. Even small changes in driver behavior or trip timing can significantly impact daily fuel consumption.

We’ve added tools to visualize these patterns and provide simple, real-time suggestions. This provides companies with a clear, trackable path to savings that they can see on a weekly basis.

Your past systems served over 20,000 users with complex workflows. How does that experience help you design intuitive, driver-friendly tools in your current project?

Working on complex systems teaches me a deep appreciation for clarity. The best interfaces offer guidance naturally without demanding extra effort. That same thinking now shapes tools built for drivers, where every suggestion needs to feel timely, clear, and easy to follow. Even with advanced logic underlying it, the experience remains intuitive. That balance between complexity and simplicity is where the real value comes through.

Large corporations can establish AI labs and employ entire teams of data scientists. What are the unique advantages of working outside that kind of infrastructure?

Smaller setups are often more connected to day-to-day operations. There’s direct contact with the team, equipment, and data, so feedback comes quickly and clearly. Changes don’t go through multiple levels of approval—they can be tested and adjusted immediately. That helps keep development practical and focused on real needs. It’s easier to see what works and what doesn’t, without waiting for formal reviews or reports. The distance between decision and result is much shorter.

How do smaller logistics companies typically react when you introduce AI into the conversation? Is the perception changing compared to just a few years ago?

At first, there’s a lot of hesitation. Many have tried different tools in the past and felt they wasted time or money. However, the attitude shifts when we show them savings in the first month. They want things that are simple, concrete, and measurable. Once the platform integrates seamlessly into their workflow and delivers value without requiring extra effort, they’re open to exploring further.

You studied economics and artificial intelligence, published research in accounting, and have built digital tools for courts, rail systems, nonprofits, and now trucking fleets. How important is that kind of cross-domain experience when building real-world AI?

It makes a difference. I’ve worked in systems where a mistake could delay thousands of salaries or block access to funding. That teaches you to treat every calculation seriously. Logistics is similar to fuel, deadlines, and routes. My experience helped me build platforms that guide decisions in a way that feels natural to the people using them. The best systems grow from a clear understanding of both numbers and behavior.

Finally, why do you believe the future of logistics is being shaped not only by corporate headquarters but also by independent, focused innovators like yourself?

In my opinion, innovation often begins closer to the problem. Independent teams working directly with dispatchers, drivers, and managers can adjust systems more quickly and respond to real-time issues without the need for multiple layers of approval. These environments encourage practical decisions and fast iteration. While large companies bring resources and scale, smaller builders bring speed and precision. That combination shapes how the logistics sector evolves—not through strategy documents but working solutions on the road.

Source: AI for Fuel, Not for Media-Slides: Yevhen Zherdiev’s View